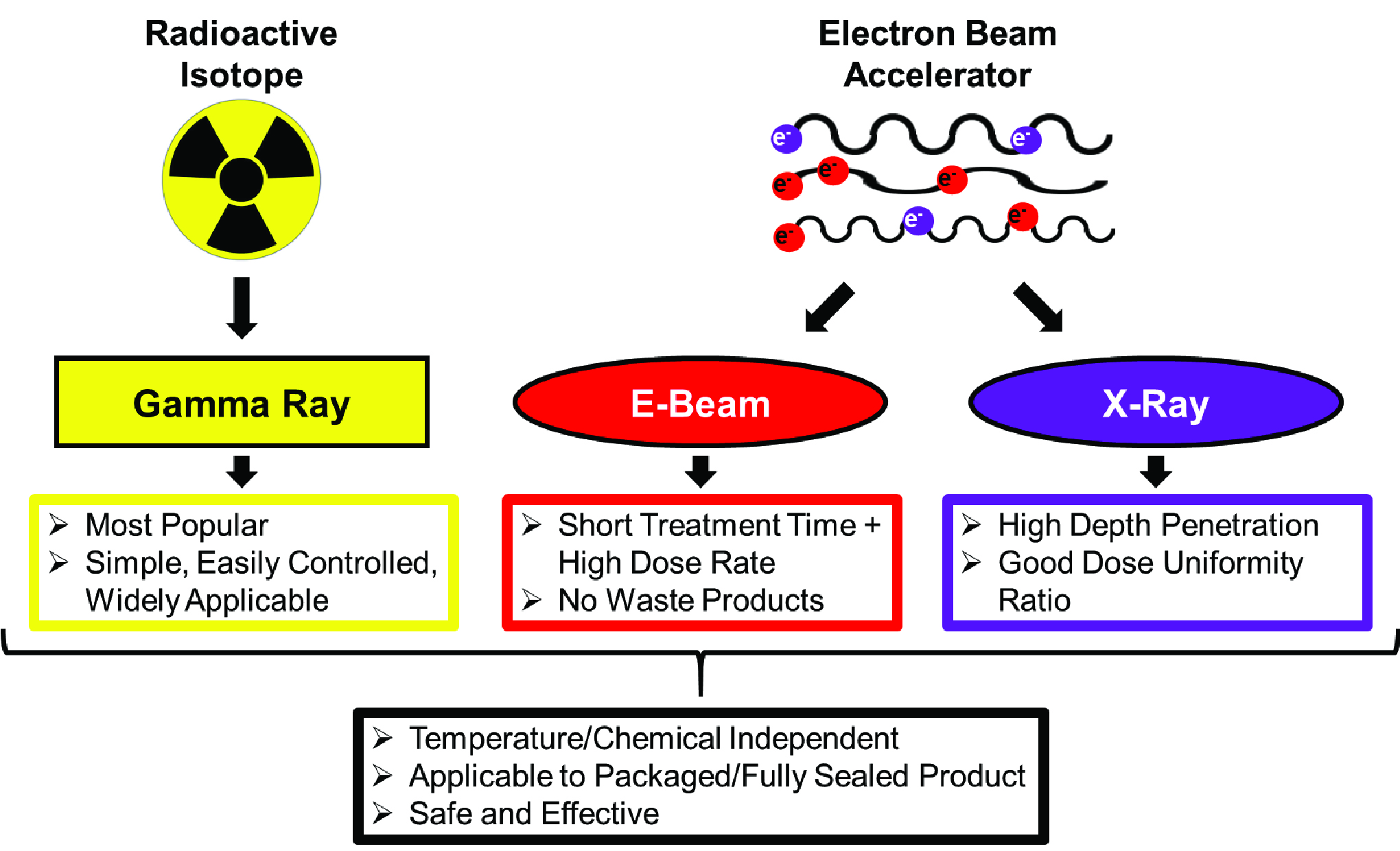

The gamma irradiation process uses cobalt 60 radiation for a variety of applications including sterilization decontamination and materials modification.

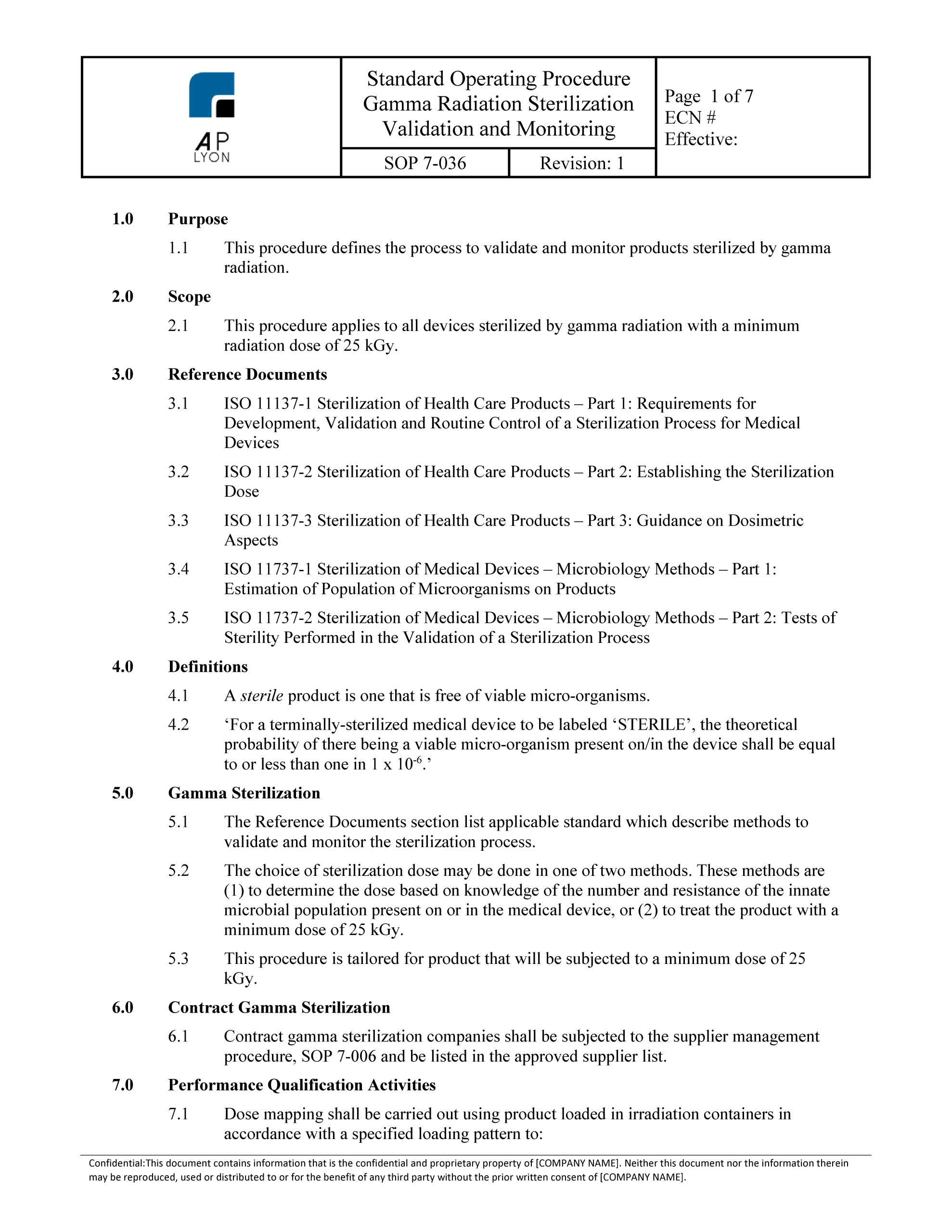

Medical device gamma sterilization.

The pcl lab frequently sees medical devices that have been subjected to gamma irradiation sterilization.

Sys 047 gamma sterilization validation procedure the purpose of this procedure is to define the requirements for gamma sterilization validation and revalidation using the vd max25 method which has been outsourced by your company to a contract sterilizer.

However compliance to.

Gamma irradiation is a simple and proven process for the safe reliable and effective sterilization of devices.

To validate the sterilization dose an accurate measurement of radiation exposure is crucial.

With a wealth of experience providing sterilization for medical devices steris ast has been providing a first.

Gamma irradiation sterilization is performed by exposing the product to a radiation source typically cobalt 60 isotope which decomposes into nickel 60 isotope firing off gamma rays in the process.

Gamma sterilization technology is very well understood safe and easy to validate.

These gamma rays can penetrate through the entire product deactivating whatever microorganisms may be present.

A list of recognized sterilization standards appears at fda s center for devices and radiological health cdrh s web site.

Gamma photons have the ability to penetrate deeply into material to provide a uniform sterilization dose throughout the volume of material.

It is an effective sterilization method due to its.

Medical device sterilization process.

Firms may elect to comply with these standards.

Eto gamma steam shelf life validation 275 00 255 00 this live webinar course will provides guidance on medical device sterilization processes.

The gamma sterilization process deploys gamma radiation in the form of cobalt 60 and an electron.

In fact it has been a go to standard sterilization method for most medical devices over the past 40 years.

Steris applied sterilization technologies ast offers the medical device industry s most comprehensive array of contract sterilization options using gamma irradiation electron beam irradiation x ray irradiation and ethylene oxide sterilization.

Safety offers proven track record in worker and product safety.

Gamma irradiation offers good penetration of dense products and is ideal for many types of materials and their packaging.